Live Chat!

SVX or Subaru Links

Old Lockers

Photo Post

How-To Documents

Message Archive

SVX Shop Search

|

SVX Network Forums Live Chat! SVX or Subaru Links Old Lockers Photo Post How-To Documents Message Archive SVX Shop Search |

IRC users: |

|

|

|

#1

|

||||

|

||||

|

The perfect Intake/Exhaust concepts

Okay I plane to throw some ideas out for discussion and would like to hear a bit of feed back,

As everyone is aware I have been working on roller throttles and Matt has also installed a set of IDTB ( he said the car goes like a stung cat), also I got a bunch flow bench work done. All this has confused me which mean its all running around in my brain till I sort it out. - Harvey has always said that on the exhaust side you need a pipe coming off, a head with out a exhaust won't work as well. In the past I was convinced he was wrong but good manours stopped me saying so. Now I am 100% convinced he is right. - Over the years you read about how people redo the intake on the head to get maxium flow and expect it to make a big difference. I am convinced that is a wrong assumption UNLESS. - People talked about how long the intake ram pipe has to be eg, longer for low revs, shorter for high rev, its suppose to do with harmonics. - Mark suggested on my roller throttles to go back to a 40mm inlet size instead of the current 45mm the SVX have standard now. (common sense would tell you that is a really stupid idea) BUT HE IS RIGHT. Lets look at the intake, I fully understand the harmonic (shock waves) have a part to play but I would like to start on the simple steps first. Here goes, when the intake valve opens the pistion is roughly on the down stroke so air and fuel runs in due to the vacum. In simple terms the amount of air that fills the chamber is directly related to the sucking pressure less the drag (restriction) on the intake parth. So reduce the restriction (port the head for example) and you will get more power. As the piston reaches the bottom of the stroke suction decreases so airflow reduces. If a engine has a long intake part then it needs to be as large as possiable to get the maxium flow into the head. So why does IDTB get such a bang for there buck if it all about in airflow restriction. Why did Mark think cutting the intake size was the right thing to do. I think the answer lays with the movment of air. With a narrower dia intake pipe but short we may have the same sort of restriction when the intake valve first opens but when the piston is no longer suction the air in the intake pipe is at such a high volicity that in continues to pump into the cyclinder under PRESSURE not vacum. Simple rule is that air under pressure contains more fuel and Oxygen then when its under vacum. The flip side to this is that you can delay the closing of the intake valve for a longer time when its on the up stoke due to the air raming against it. Back to harmonics/sound waves, I would suggest that the issue is closing the valve before the air/pressure wave gets back out the intake. In other words lower revs mean slower air velocity in the intake for a given size, the soluation is to either lengthen the parth (Ram Pipe) and or reduce the intake diameter. So team jump in, feel free to disagree with me I won't ake it personally. Have a great day. Tony

__________________

1995 - SVX 700,000 K Mine, DMS Struts to lift car 2in. Tyres Wrangler Silent Armor 235/70R16, PBR Radiator. 6 speed with DCCD and R180 rer diff, Heavy duty top strut mounts front and rear. Speedo correction box fitted. New stero (gave up on the old one). Back seat removed and 2 spare tyres fitted for desert driving. ECUTune SC sitting in the box for the next SVX. 1992 - SVX 255 K Wife (Want to stay Married so not allowed to fit SC) 1992 - SVX Pearl with black roof race car roll cauge etc ready to race. Ex Tasman Targa car. 1995 - SVX Green low k mint condiation. 1995 - SVX Rally car, ex Matts car. Now to be used on track. 1992 - SVX red & Black being converted to Mid Engine. 1995 - SVX Red 143,000 bit rough. Owned 5 others Subaru back to a 1974 1400 GSR. Last edited by Dessertrunner; 03-29-2011 at 02:58 AM. |

|

#2

|

||||

|

||||

|

Re: The perfect Intake/Exhaust concepts

What about variable length intake runners?

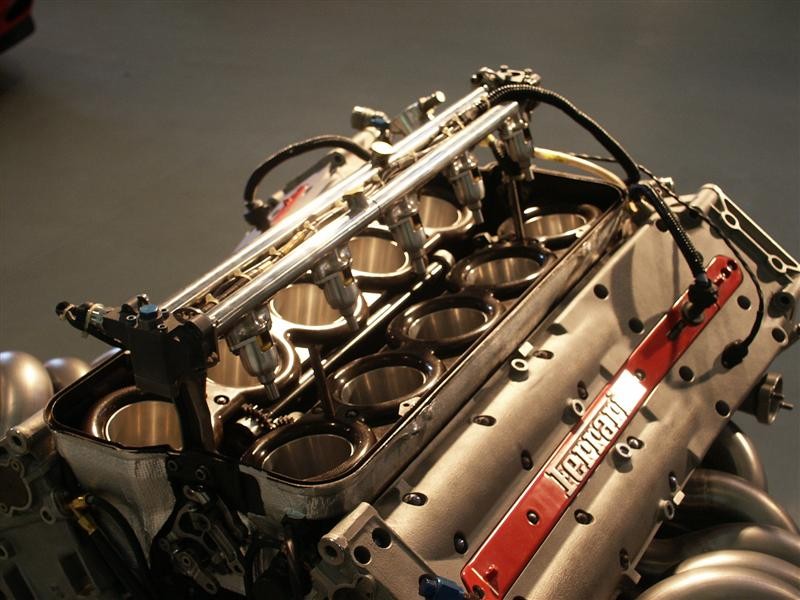

Link Here's a pic of Farrari's F1 system from 2005, I think.  You did say "perfect Intake..." didn't you? Just throwing out an idea. There's also this thingy which may help tune the harmonics.

__________________

'92 LS-L "Bandit" #362 formerly dark teal, repainted by prev owner  Mods: ECUTune 2v7f, Earthworm bushings, Pioneer DVD/Bluetooth phone, Infinity Reference all around, tint, 17" wheels, custom seat belt computer, velcro visor Buying parts is like car payments. Someday she'll be all mine. Last edited by K_Dub; 03-30-2011 at 01:07 AM. |

|

#3

|

|||

|

|||

|

Re: The perfect Intake/Exhaust concepts

variable length would be awesome!

I love how the fuel rails blow down into the intake, such a gorgeous piece of high horsepower machinery yes, smaller intakes can yield higher velocity, allowing air into the chambers allowing for more power, but longer tubes can make more useable torque for summer applications, Ford Duratecs have split ports (theres many more motors) where butterflys cover the short runners under 2.4k and opens after to allow more air to flow in but keep the large vacuum from having a longer narrower port. my cousin has a monster 2002 sport cougar with a 3.0 duratec, you can feel when they open. when I was building some sick demented flathead motors, (jr drag minibike motors... haha... 25hp briggs  ) I learned out the hard way that biggerintakes wasn't always the way to go, and in the case of exhausts on the little briggs you added a reducer to bring the ID down just a little, or you couldn't gain velocity out of the exhaust, you also added material to the inside of the intake to make it smaller, yet it was bigger around the throat and valve head to make more power, It was also important not to smooth the intake side mirror finished as this didn't allow for atomization of the gas via turbulence. ) I learned out the hard way that biggerintakes wasn't always the way to go, and in the case of exhausts on the little briggs you added a reducer to bring the ID down just a little, or you couldn't gain velocity out of the exhaust, you also added material to the inside of the intake to make it smaller, yet it was bigger around the throat and valve head to make more power, It was also important not to smooth the intake side mirror finished as this didn't allow for atomization of the gas via turbulence.its a key blend of velocity and good flow, smooth edges, and ive always assumed my ford truck would run better high with short runners, but i like my low end tourqe of the long monster, and I completely agree that it could be a much better route. just dont go too small! and dessertrunner, awesome work! Last edited by Jay Wrix; 03-30-2011 at 01:32 AM. |

|

#4

|

||||

|

||||

|

Re: The perfect Intake/Exhaust concepts

Hi Guys,

Would love the variable intake design if I could make it work. A question how do we define what to small or to large for the intake, I fully understand its a matter of trial and error but I wonder if I can fit a pressure transducer in the intake against the valve to see what is happening. Have to check if the PLC can collect the data. Would need to do 4,000 reads per minute at a minium which should be no big deal also would need to have a timing point such as valve closing. Thanks for the thought food. One other crazy question has anyone heard of heating the fuel before its injected. The reason I as is that it would mix better, I don't think it will increase pre ignation much but the amount of heat it would be carrying is low in terms of the total cyclinder fill. Tony

__________________

1995 - SVX 700,000 K Mine, DMS Struts to lift car 2in. Tyres Wrangler Silent Armor 235/70R16, PBR Radiator. 6 speed with DCCD and R180 rer diff, Heavy duty top strut mounts front and rear. Speedo correction box fitted. New stero (gave up on the old one). Back seat removed and 2 spare tyres fitted for desert driving. ECUTune SC sitting in the box for the next SVX. 1992 - SVX 255 K Wife (Want to stay Married so not allowed to fit SC) 1992 - SVX Pearl with black roof race car roll cauge etc ready to race. Ex Tasman Targa car. 1995 - SVX Green low k mint condiation. 1995 - SVX Rally car, ex Matts car. Now to be used on track. 1992 - SVX red & Black being converted to Mid Engine. 1995 - SVX Red 143,000 bit rough. Owned 5 others Subaru back to a 1974 1400 GSR. |

|

#5

|

|||

|

|||

|

Re: The perfect Intake/Exhaust concepts

Quote:

I have been studying it since I got my first two-stroke bike, in ’53. Intake design has evolved over that time.‘60s early ‘70s the engines were designed to use the gas inertia, that occurred in the inlet and the exhaust. This way the gas running into the cylinder continues to ram in, even though the piston is coming up on the compression stroke, trying to push it out. The same inertia process is use in the exhaust pipe. When the exhaust valve opens the 65psi of gas pressure charges down the exhaust pipe, the inertia of the gas flow causes a low pressure to develop in the cylinder to evacuate the remaining gas and reduce the pumping the piston would have to do when it is rising on the exhaust stroke. If the engine was a low speed engine, the low pressure caused by the exhaust inertia, lasted till the inlet valve opened, to start the inlet flow. To this end the engines had long exhaust pipes, and inlet tracts of a smaller diameter to enhance the gas velocity and inertia pressure, but these type of engines developed their maximum torque at a low speed around 3000 rpm, so the maximum power was developed around 5500. To get more power, the engine has to run at a higher speed, and the speed of the gas inertia is too slow to continue to do the job. Instead of the exhaust low pressure lasting till the inlet valve opens, it only lasts long enough to evacuate the gas and reduce some of the piston’s pumping loses. So we have lost the effect of the exhaust pulling the inlet gas in on overlap. It is the length and weight of gas that takes too long to start moving, for the faster rpm. This is why the SVX has the inertia system working till 4000 rpm, then changing to the resonate system to extend the rpm that the maximum torque is delivered. The work that the inertia pressure was doing to push the gas in from outside the cylinder, the sound pressure waves will do from inside the cylinder, using the resonate system. The Inlet tract has to be shorter to reduce the time, the gas takes to start moving and a larger diameter to reduce friction. The SVX has the inlet resonate length, from the inlet valve to the plenum, of about 15” to 17“ to produce the torque at the desired speed of 4800. To raise the rpm of maximum torque to 6500, we need to reduce the length of the inlet tract to about 13” to 14”, and reduce the length of the exhaust pipe to about 44”. All these lengths depend on the actual valve timing used. With this system the exhaust is the start of the induction sequence. When the exhaust valve opens the 65psi of gas pressure still charges down the pipe to produce the low pressure to evacuate the cylinder and reduce the pumping loses. At the same time a sound pressure wave starts down the exhaust pipe till it reaches a box, expansion chamber, where it expands to be replaced with a negative pressure wave, that travels back up the pipe to reach the cylinder in time for the inlet valve to open. The low pressure created, starts the inlet gas flowing into the cylinder even before the piston starts down. The negative wave from the exhaust continues to travel up the inlet pipe as a negative pressure, reaching the open end of the ram tube to expand and be replaced by a positive pressure wave that travels back down the tract, meeting the piston about half way down the bore. Because it can’t expand, it is reflected back as the same positive pressure wave to the top of the ram tube, where it does expand and is replaced with a negative pressure wave to travel down to the piston around the bottom of the stroke and is reflected back as the same negative pressure. So we have a negitive pressure in the cylinder right through the last 60* of the inlet stroke. It is this negative pressure that is created in the cylinder to increase the flow into the cylinder, that the older inertia wave did in the old engines. Instead of a positive pressure outside the cylinder pushing the gas in, we have a negative pressure inside the cylinder pulling it in. . Quote:

Quote:

Harvey.

__________________

One Arm Bloke. Tell it like it is! 95 Lsi. Bordeaux Pearl, Aust. RHD.149,000Kls Subaru BBS wheels. 97 Liberty GX Auto sedan. 320,000Kls. 04 Liberty 30R Auto Premium. 92.000kls. Last edited by oab_au; 04-15-2011 at 11:53 PM. |

|

#6

|

||||

|

||||

|

Re: The perfect Intake/Exhaust concepts

I have a couple of thing that need clearing up.

You and other mention about long intake lengths I accept that if they are to long you can't get the veloicty of the air up at higher speed due to friction. If the lenght of the inlet is fixed then its the diameter of the inlet that counts. I dispute the general statment of all the so call experts (I am not picking on you) that at lower revs you need longer inlet pipes. What it does not seem to be taken on board is that the diameter is more critical. You post talked about air velocity which I think is the most important point. Next burning question for me is, It is my belief that the standard SVX engine will give a major lift in power just by change to ITB even at revs of 4k. My logic is simple the standard manifold on the SVX has 45mm inlets, at that size there is no way in the world that you can get the benfits of pressures feed from high velocity air. The designers of the SVX engine are all about compromise. According to the manual the current SVX engine is getting plenty of air at that rev. Have you run the current SVX intake on a simulator to see what the intake velocity was? Tony

__________________

1995 - SVX 700,000 K Mine, DMS Struts to lift car 2in. Tyres Wrangler Silent Armor 235/70R16, PBR Radiator. 6 speed with DCCD and R180 rer diff, Heavy duty top strut mounts front and rear. Speedo correction box fitted. New stero (gave up on the old one). Back seat removed and 2 spare tyres fitted for desert driving. ECUTune SC sitting in the box for the next SVX. 1992 - SVX 255 K Wife (Want to stay Married so not allowed to fit SC) 1992 - SVX Pearl with black roof race car roll cauge etc ready to race. Ex Tasman Targa car. 1995 - SVX Green low k mint condiation. 1995 - SVX Rally car, ex Matts car. Now to be used on track. 1992 - SVX red & Black being converted to Mid Engine. 1995 - SVX Red 143,000 bit rough. Owned 5 others Subaru back to a 1974 1400 GSR. |

|

|

|