This coat (clear coat ) is going on on with the rim cooling off to ambient air temperature ( 7 C ). Also, I'm putting the hanging / ground wire around the rim's center ( inside where there'll be no coating ) and it'll be short / tight enough so that I can just lift the rim up, and leave it there and just toss it in the oven. This should eliminate any un mounting "oops"

For this coat, as it's a second coat, it's time to up the air flow to the powder coating gun, and raise the setting to 40,000 Kv.

Completely coated in clear coat, both sides, in about 45 seconds..

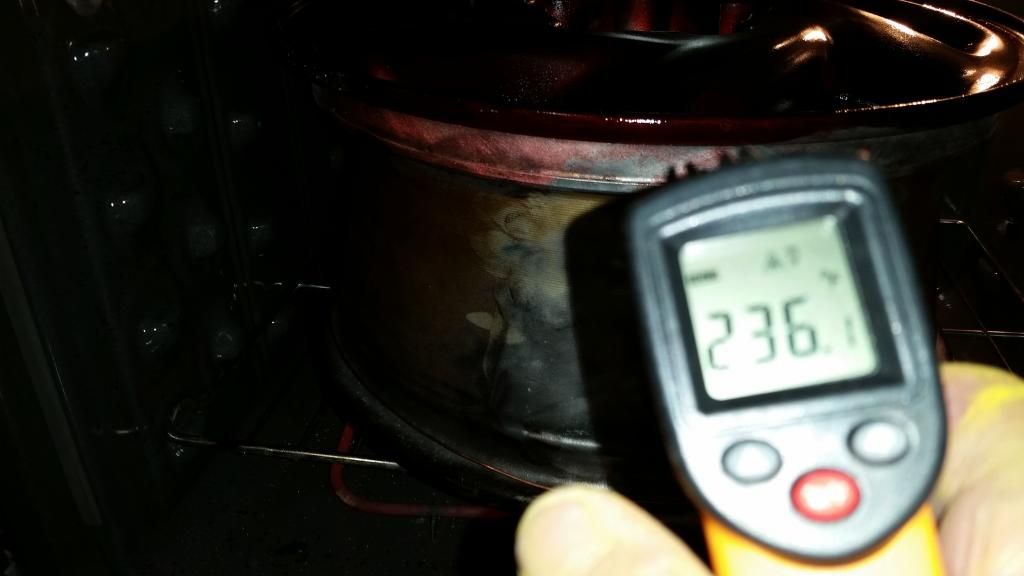

In the oven again, same issue with coating flowing, even though the rim itself is well below the temperature from which it calls for to start the timing of the curing..

sitting on top of the stove... Is it done? Hell if I know.. Timing something that is that slow to heat up is obviously it's own dog. The only thing that I could find on the University of Y&G is that you should do the part, and then test it by seeing what it would take to remove the coating, adjust methodology until the desired results are achieved, and then repeat the successful protocol for all remaining pieces Umm... yeah.. get right on that

Let's give it another five in the oven.

After it cooled off and sat for a minute.

Damn, that center just looks so .. naked.. And the centers I have look grey and weathered and ... hey! there's a five year old rattle can of Krylon gold..

Let it dry and pop it in.

Let's try a different angle..

So, at the end of the day, this is about the best shot I have of the finished product. This shot doesn't do the rim justice. At all. The colour and finish bend with the light, it looks rich and deep, it looks different in sunlight, cloud, fluorescent, L.E.D., etc. I don't know whether I like it or not. Expectation clouds perception, and this is, clearly, not what I was expecting, all "oops" aside. I see the finish on svxcess's rims and just drool. My V.P. of "feng shui" loves the rim, warts and all, he thinks it's absolutely cool, and "oops" aside, that I should do the other three exactely the same, just pass the wire wheel over them after blasting to remove the "sparklies".

At this point, I'm going to have to decide whether to go after the finish on the aluminum until it's basically flawless, or to throw a base coat on the spoke side and hope that 50,000 Kv ( my gun's max ) is enough to get the third coat to stick ( the clear coat ).

Be blunt, be brutal.. love it or hate it?

Suggestions or resources? ( especially about the curing time for something as massive as a rim) would be more than welcome.

The original idea of this post was " How much could it cost?".. Damn near lost sight of that, now didn't I?

4 rims.. you already have those... free!

some form of grinder ( for the wire wheel ) $60.00

If you have a decent compressor, a die grinder ($45.00 ) does a great job, slower but still works is a decent drill, plugged, NiMh / Li/ion, doesn't matter..

powder coating gun $60.00 - $300.00. $150.00 ( median priced )

oven ( used POS ) $0.00 to $50.00

Cost of disposables per rim.

1 can of Permatex Gasket Remover...... $9.00

4 oz. powder coat $2.00

1 wire wheel $3.00

So, if you own everything but the gun, it's $50.00 a rim and about 4 hours a rim in time. That's if they're in the condition mine were. The nicer they are, the less work they are. Less time getting them prepped. And when you're done, you still own the gun.

Other than equipment, you could do rims for less than $20.00 each.

Seriously, if you can get someone to do, and do them right, for less than $100.00 a rim.... STFU, give them the money and smile.

Would I undertake this project again, knowing what I know now? Yes, but I'd do it with something that didn't have a time frame. Speaking of that, I haven't touched the fourth rim. I'm saving that for last so that I can time it, start to finish. I've been through a few ways of cleaning / prepping the rim, and am pretty sure I've figured out the best way to do it. On the last rim, I'll stop watch the process, and have a definitive final answer on how long it takes to take a POS rim through to pristine and finished. This project needs to be done, one way or another in a few weeks. These are my winter rims, my SVX is registered to my other house in Quebec. If I get caught there after mid November without snow tires, I'll get fined and lose points off my license. They don't pull you over to check, but if they pull you over, they will check and write the ticket. They got tired of pulling people with all season radials out of the ditch in the winter. The necessity of doing it now, with a deadline is pushing other things aside, but sometimes a deadline is excellent motivation. This is one of them.

I actually like the whole powder coating thing. I've got a fair amount of "bits" that I'll do, which will amortize the cost per part of the equipment I bought down to a reasonable level. The V.P. of biological engineering managed to T-bone a fire hydrant with the John Deere and severely whuuped the front crash guard. Straightening the bumper and a coat of the liquid black are definitely on the "to do" list for the winter. I'll find a metal enclosure big enough to hang a body in, insulate it and use the current oven for parts to power it before the spring.

That being said, I'm not adverse to things to "practice the craft" on.. This offer is good until I withdraw it...

Ship me a part, prepped for coating, with a return mailer prepaid, and I'll coat it, bake it, and send it back within a week. $5.00. If you want it prepped ( that means it'll fit in a blast cabinet ) it's $10.00. Once again, with a prepaid mailer to get it home to you. My blast cabinet will fit a 16 inch SVX rim... barely.. and leaves me almost no room to work on it, so, please.. make sure the items are smaller. Please. I bought 8 finishes and a clear coat. Email me for a link to the colours if you are interested. I can attempt custom colours as I have the necessary bases to attempt to match any colour chip you send me. 50% off my end will be donated to the maintenance of this website. ( maybe enough money to upgrade the server so that we can host our own images, and not use "Photobucket", which eventually expires

) Do NOT send me your front subframe! , but smaller bits are welcome! Lol. Any part sent to me may, (and probably will ) be documented, from start to finish and put with all pertinent details into a thread that would, hopefully, share the knowledge necessary to be able to competently do it yourself, with best results and minimum investment. Yes, the whole SVX community may see your alternator pulley, naked, with all it's flaws exposed. Such are the sacrifices we must make for the advancement of the beautification of our collectibles.